-

Membership

Membership

Anyone with an interest in the history of the built environment is welcome to join the Society of Architectural Historians -

Conferences

Conferences

SAH Annual International Conferences bring members together for scholarly exchange and networking -

Publications

Publications

Through print and digital publications, SAH documents the history of the built environment and disseminates scholarship -

Programs

Programs

SAH promotes meaningful engagement with the history of the built environment through its programs -

Jobs & Opportunities

Jobs & Opportunities

SAH provides resources, fellowships, and grants to help further your career and professional life -

Support

Support

We invite you to support the educational mission of SAH by making a gift, becoming a member, or volunteering -

About

About

SAH promotes the study, interpretation, and conservation of the built environment worldwide for the benefit of all

On Accumulation: Phosphorous and the Global Metabolic Rift

Architectural historian Jasper Ludewig is a lecturer in the School of Architecture and Built Environment at the University of Newcastle in Australia. He earned his PhD from the Sydney School of Architecture, Design and Planning at the University of Sydney in 2020 and his Bachelor of Design in architecture from the University of Sydney in 2012. He currently serves as associate editor of Architectural Theory Review.

Through the 2023 H. Allen Brooks Travelling Fellowship, Dr. Ludewig hopes to gain insight into the landscapes, structures and processes implicated in the history of resource subimperialism throughout the nineteenth-century South Pacific. He will focus on the period between 1880 and 1919 when British, German, Anglo-German and Anglo-French consortia extracted rock phosphate from hundreds of islands for use as an industrial fertilizer. All photographs are by the author, except where otherwise specified.

Fig. 1. Tyntesfield House as seen from one of the many ornamental gardens flanking the building.

Tyntesfield is an extravagant Gothic Revival house and estate located just outside Bristol in Somerset. I visited during summer, its large carpark heaving with day tourists eager to inspect the ornamental gardens in full bloom. Well-kept gravel paths weave their way through the 540 acres of land passing by woods, kitchen gardens, orchards, and pasture. In the gift shop café, set in a former model farm (figure 4), visitors can purchase decorative tea towels and fake plants in rustic pots alongside David Matless’s Landscape and Englishness (2016) and Oliver Rackham’s The History of the Countryside (1986). The sour smell of scones and a gregarious murmur fill the air. I’m dressed in all black—an occupational hazard on such an irregularly warm day—and I stand out like a sore thumb. Volunteers are stationed across the site in large numbers and treat me with something between curiosity and suspicion, a situation not helped, it would seem, by my Australian accent. Gazes wander and conversation stalls completely, however, when I mention the reason behind my visit: guano.

Fig. 2. The large estate stretches across 540 rolling acres, often concealing Tyntesfield House from view.

Fig. 3. The walled kitchen garden under cultivation.

Fig. 4. A former model farm building now serves as a café and gift shop.

The Georgian farmhouse that once stood on the site now occupied by Tyntesfield House was purchased by William Gibbs in 1844—three years before his company, Antony Gibbs & Sons, acquired a monopoly for the supply of Peruvian guano to Great Britain. From initial shipments of less than 200 tons in 1842, rates of guano importation increased to 435,000 tons by 1862, the final year of the Gibbs guano monopoly.1 Mining targeted the rich deposits of the Chincha Islands, which, as I discussed in my previous report, eventually also supplied the Australian colonies with the highly effective fertilizer. According to Jane Hutton, the Chinchas “appear like three giant barnacles latched onto the horizon […] immersed in an underwater tumult of debris” drawn up from the ocean floor by the Humboldt Current.2 This debris nourishes the microorganisms upon which anchovies feed, who themselves routinely fall prey to the three main bird species responsible for the Chincha guano deposits: the guanay cormorant, Peruvian booby and the Peruvian brown pelican, their nests dotting the islands together with sea lions, penguins and terns.[3] Centuries of low rainfall and the baking tropical sun converted the bird excrement into the richest deposits of nitrogen and phosphorous known to the mid-nineteenth-century world. Following positive chemical testing of samples in the early 1800s, European trading companies, including Antony Gibbs & Sons, weren’t far away.

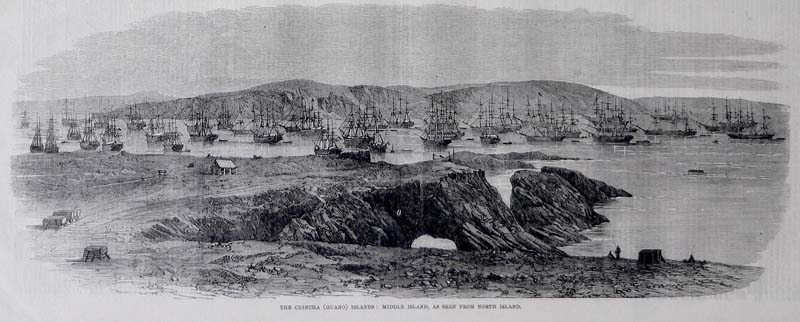

Fig. 5. The Chincha (Guano) Islands: Middle Island, as seen from North Island. Source: The Illustrated London News, February 21, 1863, 200.

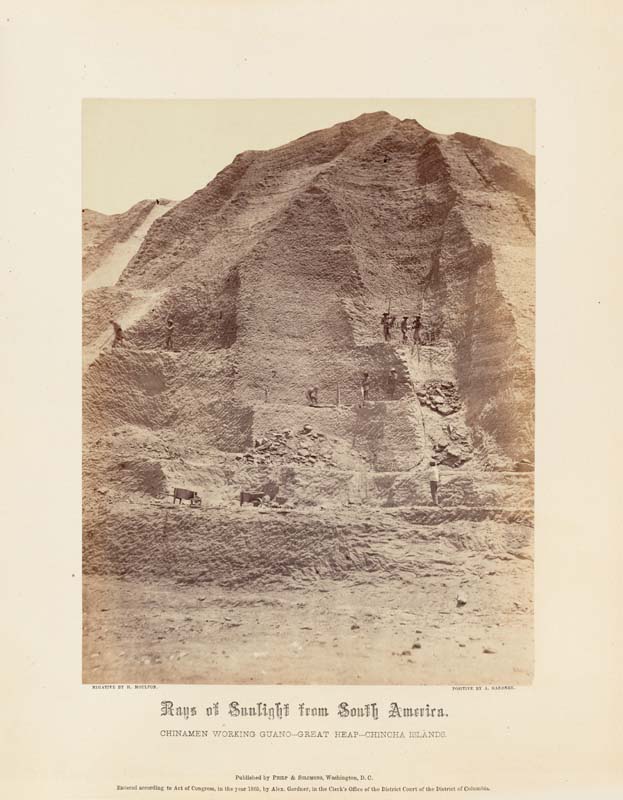

Fig. 6. Chinese labourers working the “Great Heap,” Chincha Islands. Source: Alexander Gardner, Rays of Sunlight from South America, 1865, New York Public Library, https://digitalcollections.nypl.org/items/84c5d6c1-b6d8-d30e-e040-e00a18065090.

The guano trade operated on the Chinchas had sweeping and violent repercussions for the ecology of the islands and the workers transported to them. Accounts from the 1850s describe 100 ships being loaded simultaneously as hundreds more waited offshore (figure 5).4 Contemporary photographs depict the staggering deposits of guano and the scale of the systematic efforts to raze them to the ground (figure 6). Those tasked with doing so were typically indentured Chinese laborers, contracted in the tens of thousands under coercive terms as part of the so-called “yellow trade” (la trata amarilla).5 As Edward D. Melillo has suggested, companies such as Antony Gibbs & Sons, “faced with a post-slavery world, used new configurations of the long-distance labor trade to extract maximum surplus value from their workers” who were, in the process, transformed into debt peons.6 From the moment “workers were bonded along the Pearl River Delta,” explain Lola Loustaunau et al., “the disruption of human metabolism was constantly present,” often resulting in disease and death. Mortality rates during the five-month voyage to Peru reached 42 percent during the period of the Gibbs monopoly owing to the abhorrent conditions and treatment aboard the vessels. Once on the islands, workers lived in primitive barracks and received minimal rations and water. Soldiers were tasked in part with preventing worker suicides. Mining was conducted up to seven days a week, spent prying the guano apart using hand tools under the direct sun before breaking the larger mounds into smaller quantities for loading, releasing toxic ammonia vapours. Workers regularly died in the pits in which they worked, their bodies left where they fell as their colleagues were forced to continue working around them.7 As Loustaunau et al. conclude, what firms such as Antony Gibbs & Sons required in order to make the Peruvian guano trade profitable was “semi slave/semi-free labor that was entirely disposable, without rights or autonomy” which could, as a result, be “used up and disposed of in ways that capitalized on its superexploitative character.”8

Fig. 7. The original Georgian farmhouse at Tyntesfield was gradually surrounded by John Norton’s Gothic Revival additions during the early 1860s.

Fig. 8. The hall, living room and study are to the right, the boudoir is in the middle and the family chapel is to the left in this image.

Fig. 9. The galleried landing and clerestory above Tyntesfield’s central hall.

Between 1840 and 1880, the Peruvian guano trade delivered profits of approximately $13 billion in today’s USD, primarily to British firms and to Antony Gibbs & Sons in particular, which earned around £100,000 ($10 million USD) per year at the height of its monopoly.9 The year after the monopoly ended William Gibbs commenced a three-year period of renovations at Tyntesfield, significantly remodelling the original Georgian farmhouse according to the plans of John Norton (1823–1904) and the interior design of J. G. Crace (1809–89), both close acquaintances of Augustus Pugin. Norton’s additions subsumed the existing house within a constellation of new volumes centred on a double-height hall complete with a large stone fireplace and galleried landing above. Flanking the hall are the ante room, study, and library—all lined with English Oak—as well as Blanche Gibbs’s boudoir where carved wainscot panelling depicts different plants grown on the estate, including the Chilean Bellflower—a link to the Chilean saltpetre trade into which Antony Gibbs & Sons moved once the monopoly period had elapsed (figure 16). Portraits of members of the Gibbs family line the walls alongside paintings displaying rural and maritime themes—pieces in a collection estimated by the National Trust to exceed 72,000 items in total. A leering, life-size cardboard cut-out of William Gibbs looks out, inexplicably, onto the front entry of the house from a second-storey window (figure 11).

Fig. 10. The study contains antiques acquired by William Gibbs through the merchant activities of Antony Gibbs & Sons.

Fig. 11. The family chapel is in the background. William Gibbs looks out from a second-storey window in the turret to the left of the image, near the entrance to Tyntesfield House.

As I walk around Tyntesfield, navigating the ambivalent gazes of the volunteers, my mind keeps returning to the slightly confused image of an uninterrupted stream of Peruvian guano flowing onto the estate, depositing layer upon layer of material to eventually form the crystalline, lithic architecture one arch and buttress at a time. The building seems to participate in the verisimilitude of the image—its organic, Gothic features deliberately invoking an architecture that has emerged from the earth. Yet amidst the lavish display of the wealth it generated, the clearest link I can find to the guano trade in the architecture of Tyntesfield is in an otherwise unremarkable servant’s corridor leading from the hall past the kitchens to the rear courtyard abutting the Gibbs family chapel and crypt. In this corridor, a painted glass window seems to portray cormorants and boobies on small diamond panes separated by others depicting flourishing plants bearing flowers and fruit (figure 14). Other than this window, which receives no interpretation or explanatory plaque, the only reference I can find to guano on the entire estate is on a small sign in the hall: “By the late 1850s guano profits had enabled William [Gibbs] to amass a vast fortune. This wealth gave the family the confidence to embark on the grand Gothic remodelling of Tyntesfield in 1863–6.” Even here, the subtle semantic shifts in the sign’s explanation of the estate’s provenance—from guano, to wealth, to the confidence to renovate the existing house—incrementally sever the connection between the elevated form of living on display and the abhorrent conditions of the industry that funded it.

Fig. 12. Further additions made once Tynestfield House was inherited by William’s son, Antony, are visible in the colour difference in the stone.

Fig. 13. Weathering on the Gibbs family chapel.

Fig. 14. A painted glass window with cormorants and boobies, two of the bird species responsible for the guano deposits on the Chincha Islands.

My intention isn’t to be moralistic about the National Trust’s heritage interpretation at Tyntesfield; nor is it to advocate for a negative history as a corrective against this interpretation. Rather, my interest is to understand how this presentation of architecture works—deliberately or otherwise—to obscure the circumstances of its production; what that obscurity reveals about how colonial logics condition historical knowledge; and how architectural history might work to denaturalize them. These are questions that Daniel Abramson, Zeynep Çelik Alexander, and Michael Osman describe as a re-examination of the tools of architectural historiography, in particular “how practices of evidence and narrative intertwine with core concepts in history writing.”10 What might Tyntesfield be understood to evidence beyond versions of the same contracted narrative presented on the sign in its hall? What can it clarify for the history of chemification, as explored in my previous report—its origins, outer edges, and historical continuities? And what kinds of methodological approaches does the writing of such a history require in order to complicate formulaic narratives of accumulation at the center through imperialistic exploitation of the periphery?

Answers, I suggest, can be found within the broader history of agricultural chemistry to which Tyntesfield inescapably belongs. The Gibbs guano monopoly was established less than a decade after the German chemist Justus von Liebig published his vision for “a truly scientific organic chemistry” based on rational methods of analysis and experimentation.11 In 1840, Liebig’s Organic Chemistry in its Applications to Agriculture and Physiology was immediately translated into English, receiving widespread attention in the United Kingdom over the following years against the tumultuous backdrop of the Corn Laws and the Great Famine.12 Agricultural Chemistry, as the text became known, outlined a mineralist model of soil fertility, challenging the prevailing humus theory by arguing that plants subsisted primarily on inorganic elements in the soil, rather than the organic decomposition of flesh, compost or manure.13 “It must be admitted as a principle of agriculture,” argued Liebig, “that those substances which have been removed from a soil must be completely restored to it [...] A time will come when the fields will be manured with a solution of glass (silicate of potash), with the ashes of burnt straw, and with salts of phosphoric acid, prepared in chemical manufactories, exactly as present medicines are given for fever and goitre.”14 In Liebig’s model, the “magazine of inorganic matters” that determined plant growth—chief among them nitrogen, potassium, and phosphorous (NPK)—could be understood on a systematic basis and, therefore, controlled, severing the once stable connection between soil and geography, and giving rise to open, energy-intensive agricultural systems in place of traditional crop and fallow methods.15 The new “rational agriculture,” Liebig argued, was based “on the principle of restitution” and stood in contrast to the “spoliation system” of existing models, which depleted the soil as agricultural production intensified.16 This model of soil management ushered in what agricultural historians refer to as the second agricultural revolution (1830–1880): a transition period from seventeenth- and eighteenth-century innovations in crop rotation, livestock management, market centralization, and enclosure to the eventual mechanization, genetic modification, and increased chemicalization of monocultural farming during the third agricultural revolution of the twentieth century.17

Fig. 15. Greenhouses in Tyntesfield’s orangery. Small amounts of guano were supposedly brought onto the estate in the nineteenth century to demonstrate its benefits to local farmers.

Guano became an early tool for enacting this transition. Over the course of the nineteenth century, fertilizers precipitated an eighty-fold increase in the productive capacity of agricultural soils around the world.18 Although the guano of the Chincha Islands had been used for centuries by the Quechua people, and had been known of in Europe since at least the seventeenth century, the nineteenth-century threat of soil exhaustion in England, combined with gains in soil science by the likes of Liebig, retrained attention on guano’s high amounts of soluble nitrogen and phosphorous. In the six years prior to the commencement of the Gibbs monopoly, between 1841 and 1847, the average importation of guano into England subsequently increased by a factor of 130 to 220,000 tons per annum.19 This rate of extraction would double over the next two decades of the Gibbs monopoly. For Karl Marx these shifts in fertilizer use completely inverted the foundations of existing theories of ground rent in the work of classical economists such as Malthus and Ricardo. Fertility “in our days,” wrote Marx in The Poverty of Philosophy, is not “so natural a quality as might be thought.”20 No longer was it determined by the “indestructible powers of the soil,” as it had been for Ricardo, rather it could be readily improved at comparably low capital/labor cost using modern fertilizers. The globalization of agricultural chemistry in this way also functioned as a proxy for the globalization of capital.

Fig. 16. Wainscot panelling in Blanche Gibbs’s boudoir depicts botanical specimens including the Chilean Bellflower, a subtle nod to the saltpetre trade in which the Gibbs family business became involved in the 1860s.

Unlike its predecessors—poudrette, ashes, bonemeal, and dried blood from urban slaughterhouses—the nutrients of which were conveyed in an almost closed circuit from the city to nearby rural areas and back again in the form of grains, fruits, vegetables and livestock, guano was extracted and shipped to capitalist nations from distant islands under slave-like conditions. Marx viewed this dependency on exhaustible resources and their cheapening through the exploitation of labor as the major ecological crisis of the nineteenth century, famously described as a metabolic rift in which intensive agriculture no longer found “the natural conditions of its own production within itself, naturally arisen, spontaneous, and ready to hand, but these exist as an independent industry separate from it.”21 For both Marx and Liebig, the Gibbs-dominated guano trade came to represent a process in which the earth “was robbed of its richness, the soil was depleted of its nutrients, and the separation between town and country increasingly became international” on the back of a global capitalist market and more reliable long-distance trade.22 In its transgression of human and ecological boundaries in pursuit of both mineral and capital accumulation, the second agricultural revolution thus ushered in what Melillo describes as “a prolonged phase of ‘restlessness’ for both the earth and those who reshaped its contours.”23

Fig. 17. The entrance to the Museum of English Rural Life at the University of Reading.

Leaving Tyntesfield, I alight from the Bristol-to-London train at Reading on a sunny Monday morning. Walking through the center by foot, it’s not long before I arrive at The Museum of English Rural Life (MERL), an institution dedicated to recording the history of the English countryside. MERL’s displays include agricultural machinery, homewares, and thematic exhibitions, as well as a large educational garden with plant varieties of relevance to the exhibits inside. The historical locus of the museum is set out between key dates in the history of the English countryside that adorn the walls of MERL’s entrance hall: from 1801, when 80 percent of the English population lived in rural areas; to 1882, when the first refrigerated lamb arrived in the UK from New Zealand; and from 1901, when 80 percent of people lived in towns; to 1947 and the introduction of legislation designed to intensify the productivity of post-war British agriculture.

Fig. 18. The educational garden at the Museum of English Rural Life. The archive is located on the ground floor of the building.

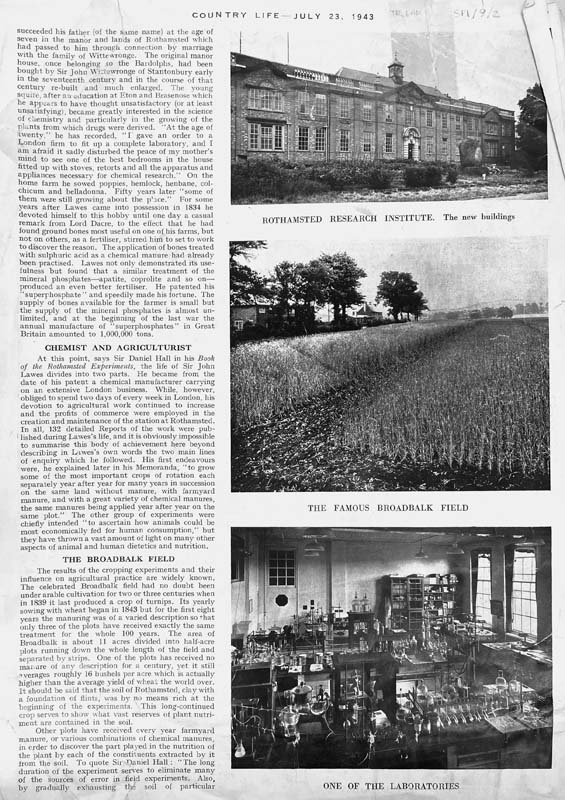

The main reason for my visit to MERL, however, is to access the archives of a company that traced its history to the commercialization of Liebig’s agricultural chemistry in the nineteenth century: Lawes Chemical Manure Company. In 1839, at the Rothamstead Experimental Station in Hertfordshire, John Bennet Lawes observed that treating bones and mineral phosphates with sulphuric acid significantly increased yields on his turnip fields. From a dedicated laboratory housed in a converted barn, Lawes repeated his trials over the following years, commencing an uninterrupted period of crop experiments at Rothamstead that would last more than a century. As Lawes explains in his memoranda, his methods involved growing “some of the most important crops on rotation year after year for many years in succession on the same land without manure, with farmyard manure, and with a great variety of chemical manures being applied year after year on the same plot.”24 The experiments revealed that the superiority of phosphates treated with acid was due to the increased solubility of the phosphorous and its subsequent accessibility to plants, effectively mirroring the characteristics of organic guano—an innovation that had eluded Liebig years earlier in his failed attempt to manufacture a commercial fertilizer of his own. Lawes quickly patented the manufacturing process in 1842 under the name of superphosphate, the implications of which for the soils of the Australian colonies I was able to appreciate first-hand while trawling through the archive of Dookie Agricultural College and Experimental Farm in Victoria, as recounted in my previous report.

Fig. 19. Images of Rothamstead Experimental Station in Hertfordshire. Source: W. E. Barber, “100 Years of Rothamstead,” Country Life (July 1943), 152.

Indeed, Rothamstead Experimental Station served a similar purpose to Dookie, bolstering the position of Britain during the rapid spread of institutions dedicated to experimental agricultural chemistry throughout nineteenth-century Europe and the United States. “For more than half century,” argues a Lawes Chemical Manure Company pamphlet at century’s end, “[Rothamstead] has been the largest and most systematically conducted experiment station in the Universe.”25 Investigations were made into the maximum number of harvests the typical soils of the earth’s crust could sustain under different cropping regimes before they were exhausted. Published reports extended the findings of Liebig and other agricultural chemists working on plant metabolism and soil fertility.26 Unlike Dookie and its European and American counterparts, however, Rothamstead was tied to a private company, effectively as its research arm, bolstering the many claims made in Lawes marketing material, which regularly boasted of “the most up to date machinery” and the best “raw materials,” enabling the company to “produce a finished product of the higher grade” with the help of its in-house chemists.27

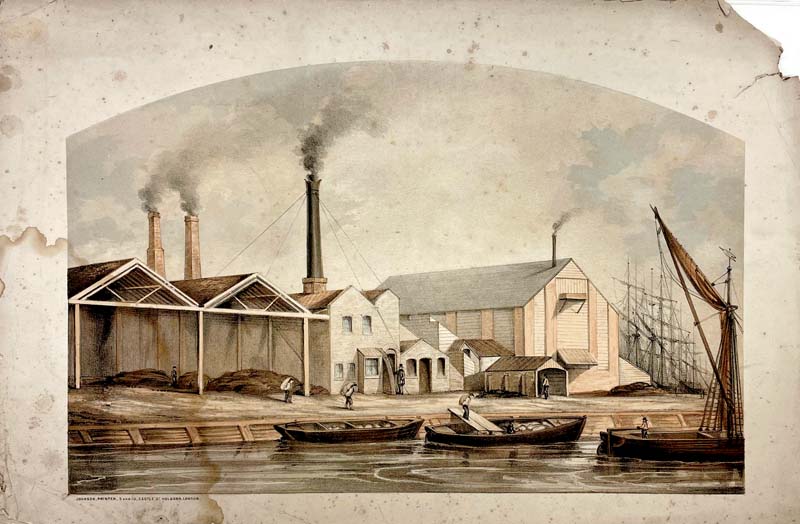

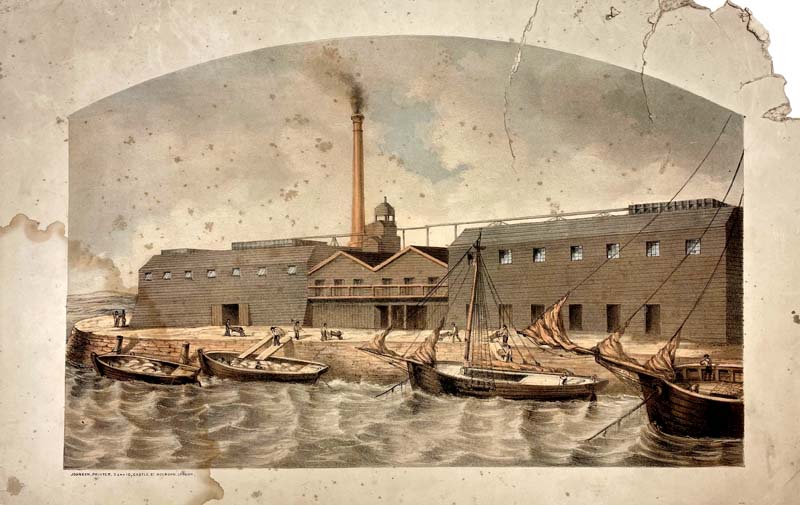

Fig. 20. Lawes Chemical Manure Company at Barking in c. 1850. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

Fig. 21. Lawes Chemical Manure Company at Barking in c. 1850. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

Fig. 22. Aerial view of Lawes Chemical Manure Company at Barking in c. 1920. The village of Creekmouth is visible in the background. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

Two years after securing the patent for superphosphate manufacture in Britain, Lawes purchased 100 acres of land fronting the Thames at Barking Creek, on the outskirts of London, where he established “one of the most remarkable industrial systems of its kind” in the domain of chemical manufacturing: an “immense works” that functioned as “a universal source of agricultural profit.”28 Already in the 1850s, Lawes erected a small village, named Creekmouth, directly adjacent to the fertilizer works for company employees, complete with around 50 houses, a school, church, store, and pub. By the 1880s, warehouses, wharves, sheds, and factories were spread across 35 acres, processing 10,000 tons of Spanish pyrite per annum to produce more than double this quantity in sulphuric acid (figure 22). A wide variety of fertilizers, including Lawes’ Dissolved Peruvian Guano and “superphosphates of all grades” were produced at Barking every year, totalling 50,000 tons in annual sales between the United Kingdom, Europe, the United States, and the colonies where the superphosphate industry was still in its infancy.29 With reliable supplies in place for the production of sulphuric acid, and with the depletion of the world’s guano deposits by the likes of Antony Gibbs & Sons, chemical fertilizer manufacturers pivoted to securing mineral phosphates—coprolites and apatites—within a new geography of phosphorous extractivism spanning North America, Africa, Europe, and the Pacific Islands.

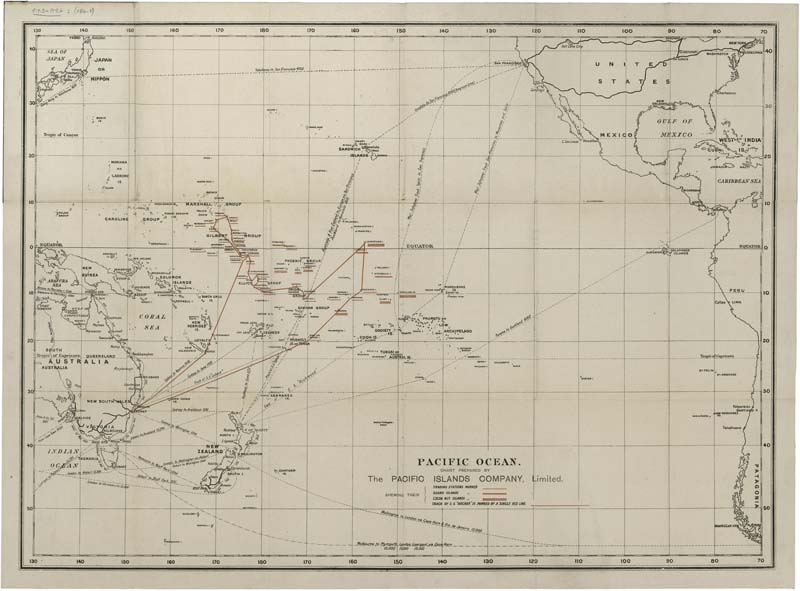

Fig. 23. Map of the PIC’s trading interests throughout the Pacific Ocean. Source: Pacific Islands Company Limited, Chart showing Trading Stations, Guano and Coconut Islands held by the Company, c.1900, National Archive of Australia, 1340195.

Fig. 24. The Scalpel stands on the site of the former headquarters of the Pacific Islands Company and its successor, the Pacific Phosphate Company. The building is tenanted, among others, by the National Australia Bank.

Fig. 25. 22 Bishopsgate towers over the remaining historic fabric of the City of London, occupying the site of the former headquarters of Antony Gibbs & Sons, just around the corner from The Scalpel.

In 1881, world production of superphosphate fertilizer amounted to approximately 1,000,000 tons, rising to 11,000,000 tons at the outbreak of World War One—a trajectory mirrored in its inverse by the decline of guano exports over the same period.30 This accelerating demand for superphosphate led to the formation of new companies seeking to supply the world’s insatiable fertilizer plants with the raw materials they now required. One such firm was the Pacific Islands Company (PIC), established by John Thomas Arundel in the 1870s to operate as a mixed business involved in inter-island trade, guano mining, and copra production, primarily on islands now located in the Republic of Kiribati (figure 23). Its headquarters were located on Leadenhall Street in the City of London, on the site now occupied by The Scalpel, directly opposite the Richard Rogers + Partners Lloyds of London building (figure 24). Around the corner, the former headquarters of Antony Gibbs & Sons has been replaced with the newly opened 22 Bishopsgate (figure 25). Both buildings recede into the glassy skyline, recent instances of the gradual erasure of the historic fabric of the City where British imperial power and privilege has been dispersed for centuries.31 As I have suggested elsewhere, the Pacific Islands Company presented a paradigmatic example of Greater British enterprise in the Pacific, its directors, staff, procurement practices and distribution networks combining the capital and expertise of a vast array of actors spanning England, Australia, and New Zealand.32 By the turn of the century, its directors included Arthur Charles Hamilton-Gordon—the Lord Stanmore—the first High Commissioner for the Western Pacific (1877–83), as well as Robert Herbert, the first premier of Queensland (1859–66) and John Bramston, former Assistant Under-Secretary of State for the Colonies (1876–98). With the PIC’s discovery of enormous deposits of rock phosphate on the islands of Nauru and Banaba, however, the company was liquidated and reformed in the early twentieth century as the Pacific Phosphate Company (PPC).

Fig. 26. More than 30 architects were purportedly employed by Lever in the realization of Port Sunlight village.

Fig. 27. Every housing block in Port Sunlight adopts a different style to its neighbors.

Fig. 28. Tudor is the predominant style adopted for the housing in Port Sunlight.

William Lever—the “millionaire soap king” and later the Lord Leverhulme—was a major investor in the new PPC venture, its sole purpose being to exploit the mining rights it had acquired on highly lucrative terms from the German (Nauru) and British (Banaba) imperial governments. Arriving in Liverpool, I travel across the River Mersey to Port Sunlight: a garden suburb and factory developed by Lever in 1888 as a model village to house his growing workforce. The guided tour offered by the Port Sunlight Village Trust leads us past the Lady Lever Art Gallery (1922), the former hospital, parks and garden allotments, a school, church, and pub—all paid for as part of a profit-sharing model Lever viewed as a form of enlightened capitalism. For Lever, who had only recently opened a coconut oil processing facility in Balmain in Sydney (to avoid paying duties on the importation of soap from Port Sunlight), Arundel’s invitation to invest in the PPC came at a fortuitous time. As part of the deal brokered between the two, Lever was able to secure a takeover of the PIC’s expansive holdings throughout the Pacific (figure 23), in particular coconut plantations in the Solomon Islands, opening-up vast reserves of coconut oil for his soap production.33

Fig. 29. Flemish brickwork was also popular for the housing in Port Sunlight.

Fig. 30. Lever lived on a large estate on the Wirral Peninsula. The house shown here is where he stayed when visiting Port Sunlight.

Fig. 31. The Port Sunlight soap works were once accessible through the brick arches in the background of this image. The garden suburb therefore ran directly into the sprawling industrial complex.

The profits being shared at Port Sunlight were funneled into England from a vast and disaggregated territory of extraction. In Lusanga on the Congo River, Lever planned an African counterpart to Port Sunlight, a “model colony” named Leverville run by the Lever Brothers subsidiary, Les Huileries du Congo Belge.34 In the British Solomon Islands, Levers Pacific Plantations eventually acquired 400,000 acres of land spread across multiple islands. But, as Gregory Cushman has argued, it was Lever’s investment in the Pacific Phosphate Company that ultimately secured the growth of Lever Brothers in the early twentieth century. Approximately 800 houses were developed at Port Sunlight during the period of the PPC’s phosphate operations on Nauru and Banaba, each household equipped with running water, a bath, and flush toilet in a village regarded as a “shrine for the worship of cleanliness.”35 Although not its core business, the extraction of Pacific rock phosphate—a kind of shadow commercial empire for Lever—marked the beginning of Lever Brothers’ transformation into a vertically integrated corporation that capitalized on the rising interest in personal hygiene and urban cleanliness, enabling its consumers throughout the anglosphere to “make use of distant ecosystems and rinse away unwanted waste—to participate in neo-ecological imperialism.”36 Following a merger between Lever Brothers and Margarine Union in 1929, the resulting company, Unilever, immediately became one of the world’s most pervasive corporations. “All of this,” Cushman concludes, “got its start with soap factories and the purchase of Arundel’s vast network of trading depots and guano islands in the Central Pacific.”37The profits derived from the PPC’s phosphate mines then allowed this network to be developed further.

Fig. 32. Approximately 800 state-of-the-art houses were developed at Port Sunlight during the period of the PPC’s phosphate operations on Nauru and Banaba.

On the back of Lever’s early investments, the PPC installed increasingly elaborate mining machinery and infrastructure on both islands, prefabricated in Europe and Australia to facilitate larger and more reliable rock phosphate exports. Preliminary processing, including crushing and drying, occurred on the islands prior to loading and shipping. To work the mines and operate the machinery, approximately 800,000 Pacific Islander, Japanese, and Chinese workers were indentured within the Pacific phosphate industry before World War One.38The records of the PPC—now accessible at the National Archives in Kew—capture the structural conditions of this massive mobilization of people onto Banaba and Nauru. Annual reports throughout the 1920s reveal the disparate terms under which different categories of employee were engaged by the company. Rations for Europeans were roughly four times those for Chinese mechanics, five times those for Pacific Islander workers and six times those for unskilled Chinese laborers. White staff were afforded more sophisticated hospitals, freshwater showers, and state-of-the-art tropical housing compared with the seawater baths and windowless, crowded dormitories built for each group of indentured workers. Wages, bonuses, instances of hospitalization, and mortality rates were characterized by similar discrepancies among the heavily racialized workforce.39Protests against these conditions were used by PPC management as justification for further controls on the islands, including the introduction of police forces and increased surveillance.40 Labor, processing, maintenance, and freight costs were regularly plotted in graphs against the fluctuating market price of rock phosphate for annual reports—figurations of corporate accumulation reflecting a managerial logic thoroughly divorced from the conditions determining productivity (figure 33).

Fig. 33. Tons of phosphate raised versus total island working costs for Nauru and Banaba, 1921–22. Source: British Phosphate Commission, Island Efficiency and Cost Figures for Ocean Island and Nauru, 1920–23, National Archives of Australia 824.

Marion W. Dixon describes this institutionalization of unfree “free labour” within the Pacific rock phosphate industry as “a coercive, racial labor regime” that further entrenched the global division of labor already evident in the mid-nineteenth-century guano trade. As Dixon argues, “this era of ‘global reconstruction’ […] was forged with the abolition of chattel slavery and through the subsequent intense struggles over labor and access to land for the continuation and expansion of commodity production in existing and new territories.”41The process of chemification is therefore not only evident in the acceleration of commercial agriculture under industrial conditions but also in the emergence of new regional hierarchies “between a generalized wage labor force in the urban-industrial complexes of the imperial states and coerced labor in the frontier regions.”42The challenge for the historian is to deduce a mode of history writing capable of traversing these disparate sites and trajectories of chemification without producing a narrative that becomes unwieldy and confused or reductive and simplistic.

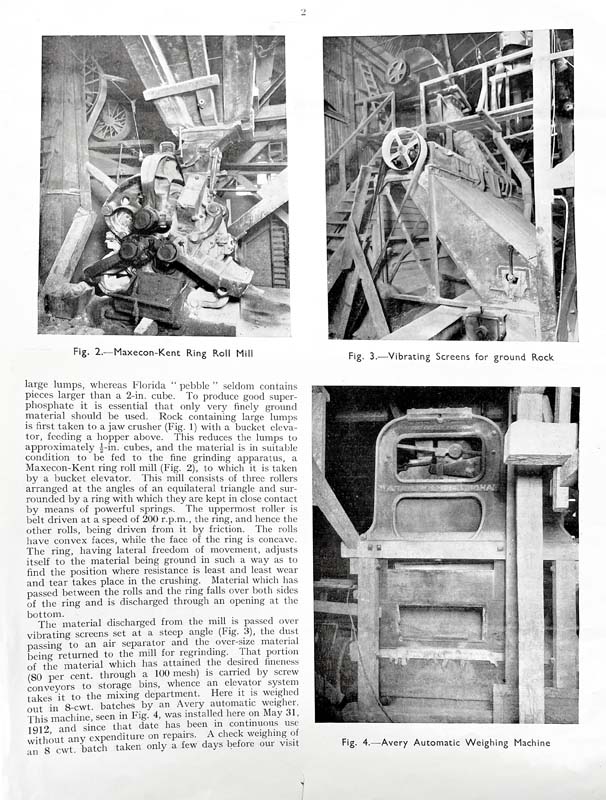

Fig. 34. The Lawes Chemical Manure Company works at Barking were celebrated in industrial chemistry literature for the scale and degree of automation with which they handled the imported rock. Source: “The Manufacture of Artificial Fertilisers,” The Industrial Chemist (April 1933), 2.

Once loaded and shipped by the PPC, Pacific rock phosphate arrived at ports around the world bearing little trace of the conditions under which it had been picked, scraped, and blasted from the coral substrate of each island. Claiming the longest history of any early-twentieth-century superphosphate manufacturer, the Lawes works at Barking were widely celebrated in industrial chemistry literature for the scale and degree of automation with which they handled the imported rock (figure 34). Shipments were unloaded at the company’s private wharf using electric cranes before being moved to storage sheds by Lister trucks and portable conveyors. Processing commenced with grading the rock through crushers until it was broken down into half-inch cubes. Bucket elevators then transported the phosphate to a fine grinding apparatus comprised of three concave metal rollers, which deposited the now powdery material onto 100-mesh vibrating screens. Screw conveyors next moved the phosphate to storage bins connected by elevators to the mixing department. Batches were automatically weighed before proceeding into the superphosphate mixer where the mined rock first came into contact with sulphuric acid. The mixing process required only one minute before the pasty product was deposited into storage dens for the remaining chemical reactions to take place (figure 35). Once finished, the dry powder was bagged and distributed to Lawes outlets throughout the wider anglosphere (figure 36).43 By 1930, superphosphate production—using similar processes to the Lawes works at Barking—had increased by 4000 percent in New Zealand and 200 percent in Australia, the primary consumers of Pacific rock phosphate after World War One. During this period, the deposits on Banaba and Nauru were set aside for the exclusive use of manufacturers throughout Greater Britain, an undertaking managed by the British Phosphate Commission until 1981.44

Fig. 35. Fresh superphosphate at the Lawes Chemical Manure Company works in Barking ready for bagging, c.1930. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

Fig. 36. Bagged Lawes Chemical Manure Company granular superphosphate, c.1950. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

On the train to Liverpool, I reflect on the dramatic effects of this influx of phosphorous into antipodean soils and what their chemical transformation meant for the material viability of settler-colonial dispossession in Australia in particular. I think somewhat differently now about what I labelled “invisibility” in my first report, by which I meant to refer to the elusive quality of fertilizer to disappear into other things and hence resist historicization. I now see the importance of retraining attention from the effects of the application of superphosphate to the material/chemical transformations involved in its production alongside the energy/work upon which those transformations relied. Doing so, as I have attempted to in this report, reveals a wider set of technics and relations that, working together, converted phosphorous into what Jason W. Moore calls historical nature. “[H]istorical natures are not ‘produced’ in linear fashion,” Moore explains, “but co-produced by the biosphere and capitalism; historical natures are products of capitalism, but also of new capitalist arrangements.”45I find it useful to think about the various technologies of facilitation—legal, financial, logistical, scientific, political—that enabled the Gibbs guano monopoly in these terms, becoming less uniform but more pervasive and reified into the twentieth century as phosphorous was no longer sought in deposits of guano but rather in rock phosphate. As Moore continues:

An ecological revolution occurs when the innovations of capital, science, and empire forge a new unity of abstract social labor, abstract social nature, and primitive accumulation. These unities are world-ecological regimes. Technical and organizational innovations allow for rising labor productivity. Ways of mapping, quantifying, and discovering new historical natures—and new use-values—allow for the rising appropriation of unpaid work/energy. And the coercive-intensive process of territorial conquest and dispossession opens new, largely uncommodified, natures to the penetration of global value-relations.46

Fig. 37. A Lawes Chemical Manure Company stand at an agricultural fair, c.1900. Source: Lawes Chemical Company Ltd. Fonds, TR LAW PH, University of Reading.

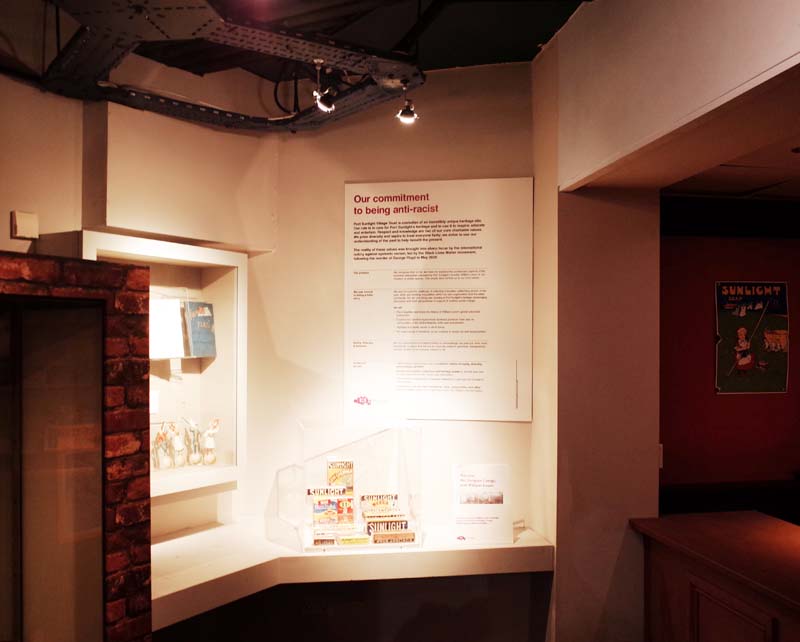

The accumulation of phosphorous in the soils of the industrialized world, the eutrophication of water bodies from fertilizer runoff, and the more indirect, unforeseen ways in which intervening in the biogeochemical cycle continues to interact with processes of climate change and ecological decline—the unintended outcomes of Liebig’s “rational agriculture”—are symptomatic of phosphorous’s transformation into historical nature.47The patents, debentures, leases, contracts, ships, dormitories, driers, crushers and mixers deployed along the way by Gibbs, Lawes, Arundel, Lever and others are the technical correlates of this transformation, incrementally calibrating unfree labor and predictable chemical processes towards the sustained accumulation of profit. As the most “architectural” extant products of this profit, Tyntesfield and Port Sunlight remain opaque—both as sites of history in general but especially in their relation to the colonial systems of extraction that made them possible. Similar opacities characterize the businesses with which they are affiliated: the absorption of Lever Brothers into the almost impenetrably large Unilever; the eventual acquisition of Antony Gibbs & Sons by HSBC; and the conversion of the PPC into the multi-national British Phosphate Commission. What Tyntesfield and Port Sunlight evidence—to return to an earlier question—is therefore as much the lucrative terms on which capital participated in the global metabolic rift of the long twentieth century as the myopic, sanitizing effects of time. A sign tucked away in a darkened corner of the Port Sunlight Museum (figure 38) tentatively suggests this may be about to change: “We recognise that, so far, we have not explored the problematic aspects of the business enterprises practised by Port Sunlight’s founder, William Lever, in our museum or public spaces.” The sign continues, declaring that the “fuller and more balanced” story the Port Sunlight Village Trust wishes to tell will “piece together and share the history of William Lever’s global colonialist enterprises.” A small pamphlet from 2022, available online, provides a brief overview of the racist history of Lever’s business practices in the Belgian Congo, promising further research to unpack Unilever’s guarded corporate archive. I leave wondering if this revisionist history will also take stock of Lever’s phosphate empire—described by Lever himself as a “gold brick”—or whether, as at Tyntesfield, it will remain consigned to the marginalia.48

Fig. 38. A sign in the Port Sunlight Museum outlining the Port Sunlight Village Trust’s commitment to anti-racism in the presentation of the history of Lever Brothers.

1 Brett Clark and John Bellamy Foster, “Guano: The Global Metabolic Rift and the Fertilizer Trade,” in Ecology and Power: Struggles over Land and Material Resources in the Past, Present and Future, eds. Alf Hornborg, Brett Clark and Kenneth Hermele (London: Routledge, 2012), 68–82.

2 Jane Hutton, Reciprocal Landscapes: Stories of Material Movements (New York: Routledge, 2020), 38, 44.

3 Hutton, Reciprocal Landscapes, 42.

4 Clark and Foster, “Guano,” 75.

5 Edward D. Melillo, “The First Green Revolution: Debt Peonage and the Making of the Nitrogen Fertilizer Trade, 1840–1930,” The American Historical Review 117, no. 4 (2012), 1029.

6 Melillo, “The First Green Revolution,” 1030–31.

7 Lola Loustaunau, Mauricio Betancourt, Brett Clark and John Bellamy Foster, “Chinese Contract Labor, The Corporeal Rift, and Ecological Imperialism in Peru’s Nineteenth-Century Guano Boom,” The Journal of Peasant Studies (2021), 11–14.

8 Ibid., 11.

10 Daniel Abramson, Zeynep Çelik Alexander and Michael Osman, “Introduction: Evidence, Narrative, and Writing Architectural History,” in Writing Architectural History: Evidence and Narrative in the Twenty-First Century, ed. Aggregate Architectural History Collaborative (Pittsburgh, PA: University of Pittsburgh Press, 2021), 16.

11 Justus von Liebig, “Ueber einen neuen Apparat zur Analyze organischer Korper und uber die Zusammensetzung einiger organischer Substanzen,” Poggendorffs Annalen der Physik und Chemie 21, no. 8 (1831), 21.

12 Pat Munday, “Politics by Other Means: Justus von Liebig and the German Translation of John Stuart Mill's ‘Logic’,” The British Journal for the History of Science 31, no. 4 (1998), 409–411.

13 Munday, “Politics by Other Means,” 412.

14 Justus von Liebig, “Organic Chemistry in Its Applications to Agriculture and Physiology,” in Liebig's Complete Works on Chemistry, ed. Lyon Playfair (Philadelphia, PA: T. B. Peterson, 1852), 63.

15 Liebig, “Organic Chemistry in Its Applications to Agriculture and Physiology,” 11.

16 Justus von Liebig, Letters on Modern Agriculture (London: Walton & Maberly, 1859), 183.

17 John Bellamy Foster, “Marx's Theory of Metabolic Rift: Classical Foundations for Environmental Sociology,” American Journal of Sociology 105, no. 2 (1999), 373–74.

18 Greta Marchesi, “Justus von Liebig Makes the World: Soil Properties and Social Change in the Nineteenth Century,” Environmental Humanities 12, no. 1 (2020): 205–226.

21 Karl Marx, Grundrisse: Foundations of the Critique of Political Economy, quoted in Melillo, “The First Green Revolution,” 1035.

25 Lawes’ Chemical Manure Company Ltd., Chemical Manures, and the great benefit derived by all crops from their judicious use (London: Lawes’ Chemical Manure Company Ltd., c.1895), 5.

26 Abbot Payson Usher, “Soil Fertility, Soil Exhaustion, and Their Historical Significance,” The Quarterly Journal of Economics 37, no. 3 (1923), 391–93.

30 A. N. Gray, Phosphates and Superphosphates (London: International Superphosphate Manufacturers’ Association, 1930), 58.

31 Amy Thomas, “Risk in ‘the Room’: Negotiating New Economic Paradigms in the Architecture of Lloyd’s of London Insurance Market,” Architectural Theory Review 26, no. 1 (2022), 14.

32 Jasper Ludewig, “‘Lonely Dots’: John Thomas Arundel and the Architecture of Greater British Enterprise in the Pacific,” Fabrications 32, no. 1 (2022): 340–67.

33 Gregory T. Cushman, Guano and the Opening of the Pacific World: A Global Ecological History (Cambridge: Cambridge University Press, 2013), 107.

34 Port Sunlight Village Trust, Racism, the Belgian Congo, and William Lever, pamphlet, second edition (June 2022), 4–5.

37 Ibid., 107

38 Ralph Shlomowitz and Munro Doug, “The Ocean Island (Banaba) and Nauru Labour Trade 1900–1940,” Journal de la Société des océanistes 94 (1992), 103.

39 British Phosphate Commission, Island Efficiency and Cost Figures for Ocean Island and Nauru, 1920–23, National Archives of Australia 824.

40 Marion W. Dixon, “Phosphate Rock Frontiers: Nature, Labor, and Imperial States, from 1870 to World War Two,” Critical Historical Studies 8, no. 2 (2021), 299.

Leave a commentOrder by

Newest on top Oldest on top